On December 8, 2025, Toray announced that it has established a technology to scale up highly durable and highly selective nanofiltration (NF) membrane elements to a practical size, which can recover lithium from used automotive lithium-ion batteries with high purity and high yield.

As electric vehicles (EVs) and other electrified vehicles become more widespread in Japan in an effort to realize a decarbonized society, there is a need to secure rare metal resources to ensure a stable supply of lithium-ion batteries, which are at the core of these vehicles. In particular, there is a need to establish recycling technology for lithium resources through the recycling of used lithium-ion batteries.

Until now, recycling of used batteries has focused on recovering expensive nickel and cobalt, and much of the lithium has been discarded. However, with the rapid spread of lithium iron phosphate (LFP) batteries, which do not contain nickel or cobalt, in recent years, there has been a growing need to recover lithium alone.

Meanwhile, Toray’s NF membranes have been used to separate and recover lithium from salt lakes, but recovery from used lithium-ion batteries requires filtering the highly acidic sulfuric acid leachate used to extract metal components from used batteries, and conventional membranes have had issues with their durability in strong acids.

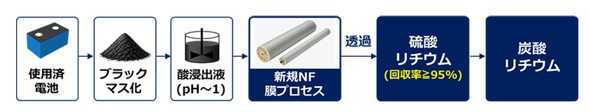

Toray therefore proposed a separation membrane technology that selectively separates and recovers lithium by filtering the sulfuric acid leachate of black mass obtained by heat-treating used lithium-ion batteries using a highly durable and highly selective NF membrane with improved acid resistance, and conducted multiple demonstrations on a research lab scale. As a result, it was confirmed that this technology can recover lithium with a yield of over 95%.

The process for practical application of lithium recovery NF membrane elements [Click to enlarge] Source: Toray

The process for practical application of lithium recovery NF membrane elements [Click to enlarge] Source: TorayThis technology will enable efficient and high-quality recovery of lithium from a wide range of lithium-ion batteries, including nickel/cobalt batteries as well as LFP batteries. Furthermore, it is expected that the increased efficiency of lithium recovery will contribute to resource recycling.

In addition, through work commissioned by the Ministry of the Environment, Toray has set its sights on scaling up by widening the width of highly durable and highly selective NF membrane elements, which combine knowledge of organic synthetic chemistry, polymer chemistry, and nanotechnology.

This scale-up has made it possible to mass-produce modules of the same size as elements currently used for water treatment applications.

This will enable application to recycling processes on a practical scale and provision of samples to customers. Currently, the company is working to establish a supply system with a view to expanding the business both domestically and internationally.

https://monoist.itmedia.co.jp/mn/articles/2512/09/news033.html